Introduce

CERAMIC BACKINGS СERABACK AND THEIR APPLICATIONS

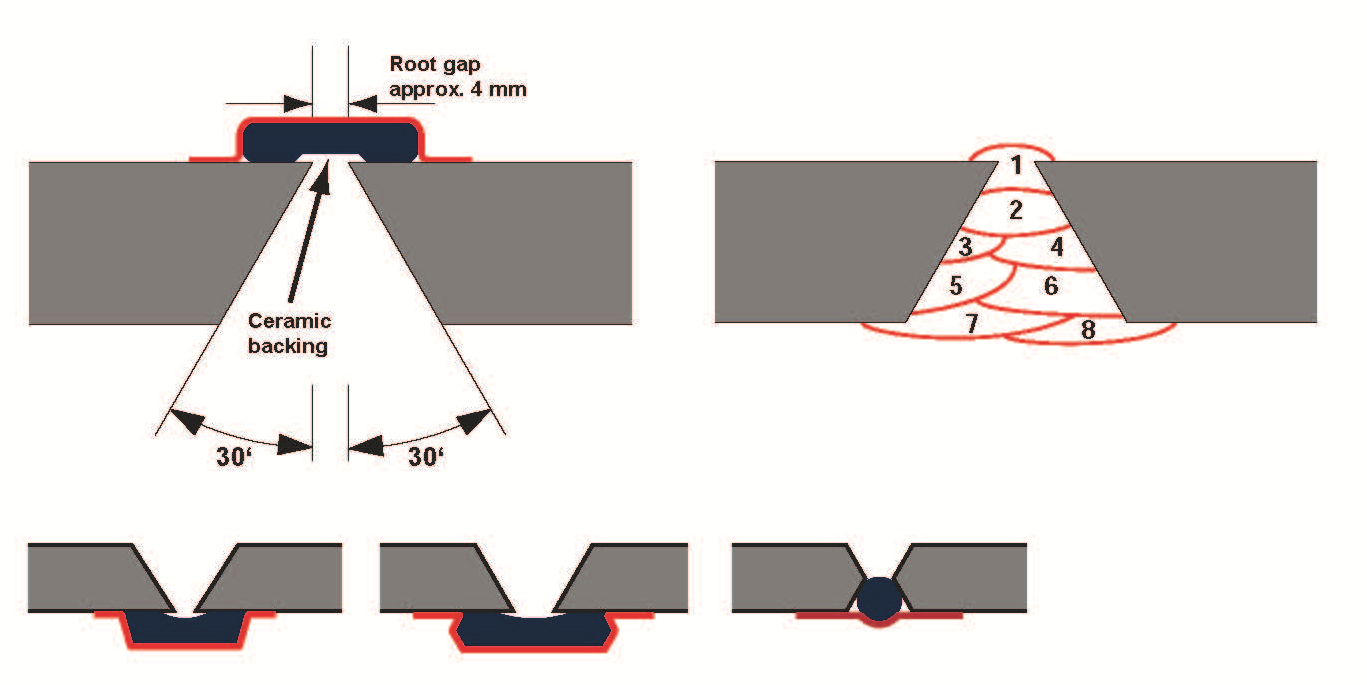

Ceramic backings СERABACK are made of sealed, high temperature resistant ceramic, from different mineral mixes (e.g. Al2O3, SiO2, Fe2O3, TiO2). When they melt, they produce a glassy slag that forms the underside of the weld seam and seals it against air entering. They are chemically neutral in the weld pool. Ceramic backings are available as ceramic blocks (~2 cm long) on a flexible aluminum foil with an adhesive edge, that can be stuck to the underside of the weld seam. They are also available as single ceramic segments (~10 to 15 cm long) for placement in metallic rails that are then attached to the work piece with magnets or other fixtures.

The ceramic backings offer special economic advantages for submerged arc welding and MAG welding with solid wires or metal- cored wires in the downhand position as well for positional MAG welding using rutile cored wires with fast freezing slag.

Ceramic backings are traditionally used in industry segments that are under pressure to keep costs low, such as shipbuilding. However, today they are increasingly used in pressure vessel fabrication, machine construction, general steel construction, tanks, bridges and plant engineering.

EXAMPLES OF CERAMIC BACKING СERABACK APPLICATIONS

APPLICATION TIPS OF CERAMIC BACKING СERABACK

- Ideal for mechanized, one-sided welding with high currents and for manual welding of root runs with increased welding parameters (MAG solid wire and MAG cored wire).

- Root runs can be produced in thicknesses that make it possible to weld filler layers (as from the second layer) with very high currents and deposition rate, without the risk of burn-through.

- Suitable for compensating deviations in fit-up, without the need to significantly adjust the welding parameters, thereby ensuring a high quality root. Irregular root gaps can be welded without time-consuming adjustments.

- In two-sided welding, expensive back grinding can usually be completely eliminated.

- Root runs welded with ceramic backing normally have a lower incidence of insufficient penetration, undercut, pores, slag inclusions and restart errors.

- One-sided welding with ceramic backing increases process reliability when root runs have to be notch-free, e.g. in the case of dynamic loading or stress corrosion.

- Due to their moisture resistance, ceramic backings are also suitable for outdoor welding. One-sided welding at the construction site can often be carried out on the inside of the component so that weather conditions do not play a role

- Dense ceramics with low moisture content are ideal for welding high-strength, fine-grained steels that require weld metals with very low hydrogen content.

СERABACK - Fiber Glass Weld Back-up Tape

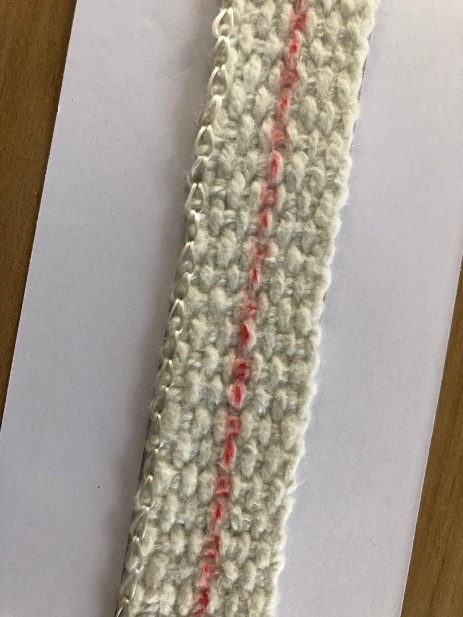

The СERABACK welding Back-up tape consists of a 30x3 mm. continuous filament fiberglass tape laminated and running down the centre of an acrylic adhesive aluminum foil tape of 120 mm wide covered with easily released siliconized paper. These adhesive edges stick to the area surrounding the root gap with the woven fiberglass tape facing the backside of the root gap.

Available in heavy duty use for up to 350 amps. For above 350 amps, different products of fiberglass band with refractory silica glass in the center are available.

The heavy-duty tapes are available in 30 meters long rolls.

|

|

|

СERABACK Fiber Glass Aluminum Tape

Heat Resistance Technical Information:

- Adhesive: 400°C

- Aluminum Foil Tape: 600°C

- Fiberglass Strip: 1000°C

- Suitable for applications up to 350 Amps

Advantages:

- Facilitates perfect weld penetration and proper merging

- Saves argon gas as no purging will be necessary, which results into less cost on purging gas

- Imparts X-ray quality back beads on root pass

- Makes process faster as it saves time in preparation and assemble. Welds one side only

- Deposits more weld metal

- Root weld and fill in one pass

- Eliminates back chipping

- Eliminates defects and reworks

Eliminates costly unnecessary grinding and gauging

Provides incombustible, high temperature stability. More flexible, low thermal conductivity, good thermal shock resistance, good mechanical and chemical agents resistance, good electrical properties.

By using fiberglass weld back up tapes, Welding COST is saved approx 50 to 60% whereas welding TIME is saved by 50%. RESULTS are 100% RADIOGRAPHIC WELDING. No Back CHIPPING, No Back GRINDING or Gouging, No PURGING required